Contact Us

Phone Number

Gaurav Bhatnagar:

+971 508457928

Location

Aeroseal Energy Solutions LLC Office no #210, Sheikha Mal hra Ahmed Majid Al Ghurair Building,

Al Nahda, Al Qusais 2, Dubai, UAE

Pin Code: 237951

The Process

Step 1: Prep of the ductwork

Protect vital equipment and create pressure inside the ductwork

All registers are blocked or taped to pressurize the ductwork. Vital components, such as furnaces, coils, smoke detectors, and other sensors, are protected to prevent contact with the sealant. The supply and return duct systems are typically sealed separately.

Step 2: Connect the Aeroseal Equipment

Attach to the ductwork and run a pretest

The Aeroseal equipment is connected to the duct system through plastic lay-flat tubing, either via an existing register or an access hole in the ductwork. A pretest is conducted to measure initial leakage, like a Duct Blaster test. These results are used in the post-seal report to verify the seal’s effectiveness and estimate the time required for sealing.

Step 3: Seal the Ductwork

Inject sealant from the inside the ductwork, sealing only where needed.

The equipment now begins spraying sealant directly into the duct system. Our non-toxic sealant is atomized and sprayed into the lay flat tubing where it’s exposed to heated air, removing moisture from the sealant make it temporarily sticky, allowing it to collect in cracks and gaps in the ductwork.

The sealant slowly builds up overtime, collecting onto itself, like the platelets in your blood after a scrap, until the gap is sealed. The entire process is monitored by our proprietary software, making automatic adjustments to pressure and flow rate to optimize effectiveness.

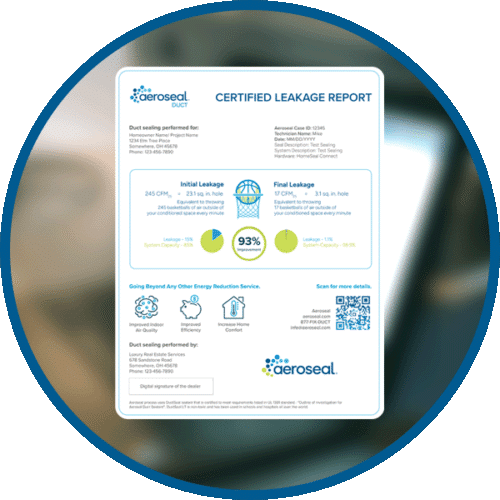

Step 4: Certify the Results

Verify final duct leakage and pack up equipment

When the target leakage rate is reached, the equipment is turned off, and any access holes are patched. Tape and blockers are removed, and the HVAC system is restored to normal operation. A detailed seal report is generated, comparing the before-and-after leakage rates to confirm effectiveness.